(858) 224-9100

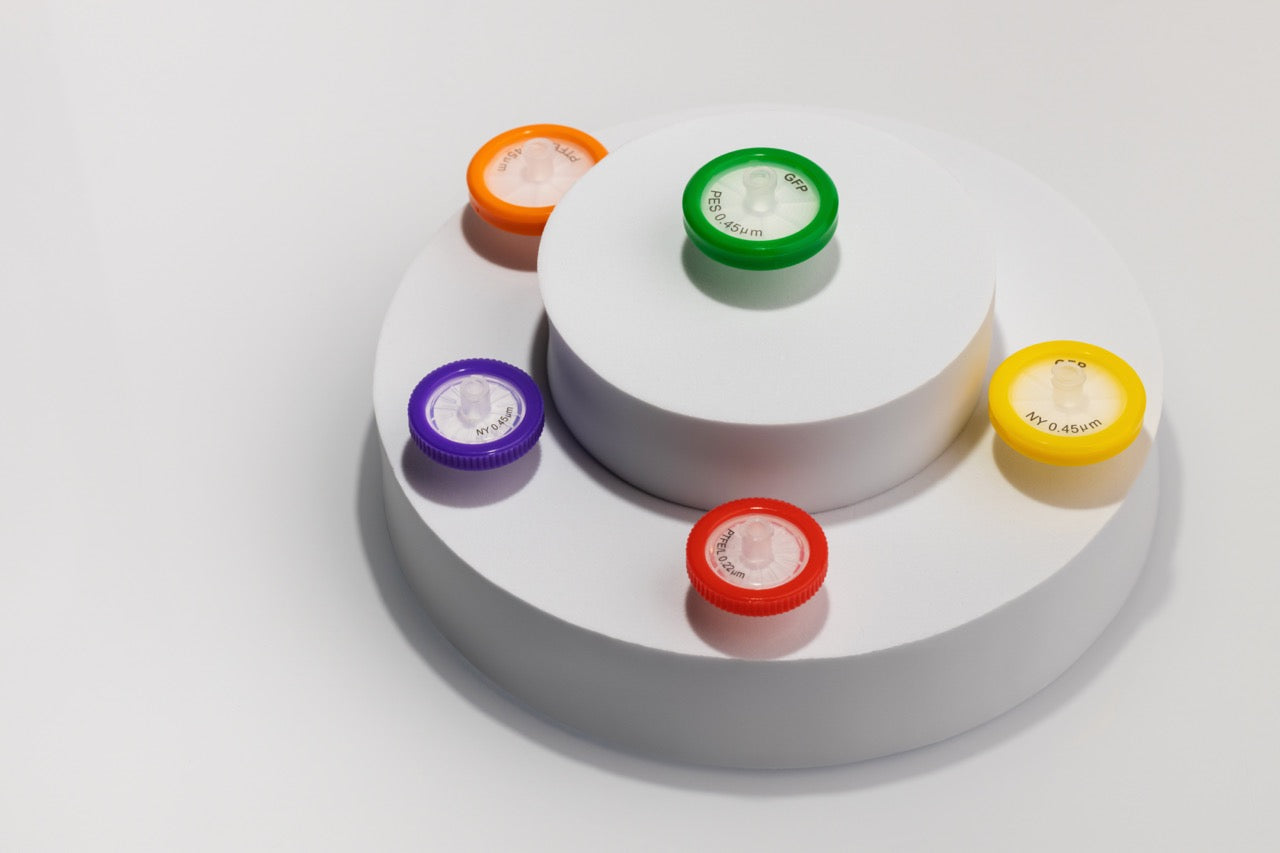

How To Choose Your Syringe Filters

Sometimes… it can get confusing to know which syringe filter to use for your application.

You have to make sure that you use the right syringe filter for your sample because using the wrong one can affect your results giving you bad data.

Plus, you can also hurt your equipment (like clogging your HPLC column) if you don’t filter correctly.

But whether you are using a syringe filter for applications in HPLC, biotech, food & beverage industry, or even pharmaceuticals, we are going to show you how to choose your syringe filter depending on the application to give you accurate data.

Let’s get started.

What Is A Syringe Filter? (And What To Look For When Choosing Your Syringe Filter)

A syringe filter is a single-use membrane tool to remove impurities from your sample.

There are many things you want to consider when choosing your syringe filter for optimal results.

These include:

- The applications for your industry

- Chemical Compatibility

- Membrane Type

- Filter Body

- Pore Size

- And Diameter

You want to make sure that all of it is perfect for your solution to get accurate data in the lab.

Choosing Syringe Filters Based on Your Application

One way to choose your syringe filter is based in the industry that you’re in. This is because you use certain solutions and you want to make sure your syringe filter is compatible to ensure you don’t mess up the sample and data.

- Ethanol testing: nylon or PES ( SFN-CQ-1030)

- Cannabis testing, mainly potency or terpenes: PTFE (SFN-BR-1013)

- Heavy metal testing: nylon (SFN-AR-1013)

- Pesticides testing: PES. You need something heavy-duty. (SFN-CQ-1030)

- Toxicology: PTFE (SFN-BR-1025)

- Environmental testing: PES (SFN-CP-2030), PTFE (SFN-BR-1025), or nylon (SFN-AR-1013)

- Harm-reduction: PES (SFN-CQ-1030) or PTFE (SFN-BR-2025)

- Pill IV: PVDF

Syringe Filter Chemical Compatibility

Membrane type affects chemical compatibility. When choosing your syringe filter, you want to double-check with our chemical compatibility chart below to ensure that you are able to properly filter your solutions.

In general:

- PTFE membranes are nearly compatible with most solvents, acids, and bases. It can be hydrophobic or hydrophilic.

- Polyethersulfone (PES) membranes are hydrophilic and have a low protein binding which means it generally offers a better flow rate and chemical resistance than the cellulose acetate membranes. It is great for tissue culture samples and buffers and also allows a higher liquid flow than a PTFE membrane. Usually, you use it for applications like ion chromatography, tissue culture filtration, and filtration of proteins.

- Polyvinylidene Difluoride (PVDF) membranes have a high solvent resistance and low protein binding making them perfect for biomedical and sterilization filtration, as well as HPLC sample prep. They are a solvent-resistant membrane that shows low levels of UV-adsorbing extractable.

- Nylon (NYL) membranes are a strong, hydrophilic membrane that is compatible with a lot of alcohols and solvents used in HPLC. It’s solvent resistant, exhibits low extractables, and is compatible with organic solvents but it should not be used when protein recovery is important.

- Cellulose acetate (CA) membranes are a mixture of cellulose diacetate and triacetate giving it a good solvent resistance to low molecular weight alcohols. Has great flow rates and very low protein binding so it’s great for protein recovery applications.

- Cellulose Nitrates (CN) membranes are primarily used for pre-filters but may not be compatible with some aqueous and nonaqueous solutions. It’s a very popular membrane because it gives one of the fastest flow rates for aqueous solutions and has great wetting properties. A great choice for trace analysis.

- Mixed Cellulose Ester (MCE) membranes are great for when you need to analyze particles that are contained either in liquids or from aerosols because it has a more uniform and smoother surface compared to a nitrocellulose membrane.

Choosing between Sterile and Non-Sterile

The way you want to choose depends on your method to ensure your data is accurate.

Sterile: these are individually packed. Recommended if you want a sterile aqueous solution. Typically used for food & beverage testing and medical testing.

Non-Sterile: these are packaged in bulk. Much more affordable than their sterile counterparts.

Filter Body

When choosing your filter body, you want to make sure you are picking the right tip and filter body for your filtration.

- If you’re looking for disposable filters, they are usually polypropylene but you want to double check with the chemical compatibility

- If you’re looking for reusable filters, polycarbonate and stainless steel are typically the most common.

Fitting

This is the attachment point of the filter to the syringe.

There are 2 main types: Luer Slip and Luer Lock.

Luer Slip fitting is “slip on,” and is held to the syringe by friction. They can be used on any syringe with a Luer adapter. Luer Lock fittings “lock” onto the syringe, allowing greater pressures to be pushed through the syringe without the filter popping off. Luer Lock Filters are only compatible with Luer Lock syringes.

Choosing A Pore Size

The pore size that you choose for your syringe filter is dependent on the sample you are using. As a general rule of thumb, the smaller the pore size the more pressure it takes to pass your sample through the syringe filter, resulting in slow flow rates.

Choosing the appropriate pore size depends on the size of the particle to be filtered out. For instance, smaller particles require smaller pore sizes. The most common pore sizes are 0.22 and 0.45um.

0.22um typically is good for most particulates, and will filter out bacteria. 0.45um filters will filter out approximately 99% of all particles but are nevertheless not enough to filter out the vast majority of bacteria.

Common pore sizes and respective purposes:

- 0.1μm: solution sterilization and mycoplasma removal

- 0.2/0.22μm: solution sterilization (bacterial removal)

- 0.45μm: general filtration and particle removal

- >0.45μm: typically used for pre-filtration

Choosing a Diameter

You want to choose a diameter based on your sample volume.

For instance, wider diameters can handle larger sample volumes. You can almost always use a wider diameter filter in place of a smaller one.

This is the “width” of the filter. Wider diameters can handle larger sample loads. You can (almost) always use a wider diameter filter in place of a smaller one.

For example, a customer wants a 25mm diameter filter, but they’re out of stock. You can substitute a 33mm diameter filter with all other identical criteria instead.

Below is the general rule of thumb:

- 4mm filters: for sample volume less than 1mL

- 13mm filters: for sample volume between 1 to 10mL

- 17mm filters: for sample volume greater than 10mL

- 25mm filters: for sample volume between 10 to 100mL. Ideal for high throughput labs

- 30mm filters: for sample volume greater than 100mL

Prefilter

Most filters usually do not have a built-in prefilter. Some, however, do have an additional, larger pored (often glass microfiber) filter built-in before their main filter.

This is because it allows them to filter more congested mixtures without getting clogged.

How To Use A Syringe Filter

This is a basic step-by-step on how to use a syringe filter to correctly filter out your results.

- Load the sample into your syringe.

- Attach the syringe filter with a solid (don’t overtighten) fit with either the Luer slip or Luer lok

- Hold the syringe vertically to wet the membrane evenly as this helps prevent air blocks and promotes a higher flow rate.

- Press the syringe gently through the filter and if possible, discard the first .25mL because if there is any contamination, it’d be within the first mL of the sample. Never put too much pressure as this could cause the filter house to burst.

- Change filter and repeat for the next sample.

Frequently Asked Questions

- Syringes. You will need syringes (Luer lock or Luer slip) to go with syringe filters. In most cases, you will also want to use glass vials for sample storage.

- You have two options here. You can either:

- Substitute a 33mm diameter filter. Just make sure all other aspects (pore size, membrane type) are identical, or

- Use a H-PTFE syringe filter of the same diameter.

Conclusion

That was a lot of information on how to choose your syringe filters but hope you found some value from it.

If you have any questions on syringe filters or are curious about which syringe filters you would like to use for your lab, you can also contact us at info@filtrous.com or with our live chat.